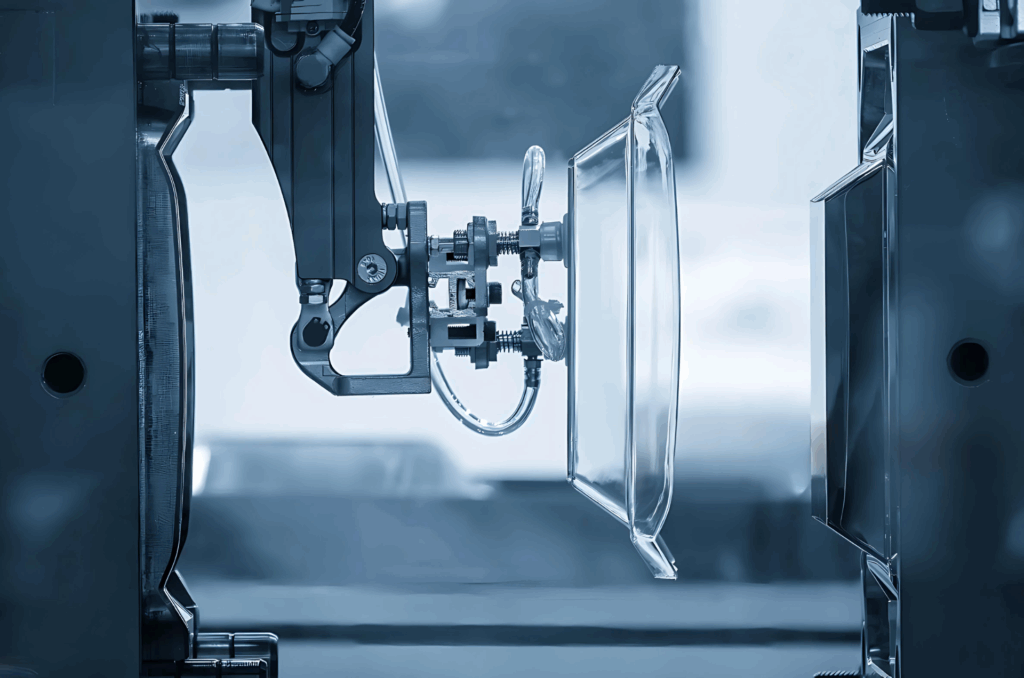

Plastic Injection Mold Services

At DMISCO, we offer end-to-end plastic injection molding services to produce high-quality, dimensionally accurate plastic parts for a wide range of industries. From functional prototypes to large-scale production, our injection molding process ensures consistent results, tight tolerances, and excellent surface finish. We work with various thermoplastics including ABS, PP, Nylon, and Polycarbonate to deliver components tailored to mechanical strength, thermal resistance, and aesthetic requirements. Our mold design expertise, combined with advanced tooling and quality control, ensures your parts are made right—every time.

Key Features of Our CNC Milling Services

Custom Mold Design

We create detailed, durable molds based on your CAD files, prototypes, or design inputs for accurate and repeatable production.

Material Variety

Compatible with a wide range of plastics including engineering-grade polymers for both functional and cosmetic parts.

Mass Production Capability

Ideal for high-volume production with minimal cycle time, reduced labor costs, and low material waste.

Post-Processing Options

Secondary operations available including part assembly, trimming, ultrasonic welding, and surface texturing.

Benefits of Our Plastic Injection Mold Services

High Efficiency

Fast cycle times make injection molding perfect for producing thousands of parts quickly, with excellent consistency and quality.

Cost Savings

Ideal for large volumes where mold cost is offset by low per-unit production expenses over time.

Design Flexibility

Supports complex shapes, undercuts, and varying wall thicknesses in a single part with minimal secondary machining.

Strong & Lightweight

Molded parts offer high mechanical strength while remaining light, ideal for automotive, electronics, and consumer goods.

Why Choose Us

At DMISCO, we combine in-house mold design expertise with advanced manufacturing technology to deliver plastic parts that meet the strictest tolerances and quality expectations. Our team supports you at every step—from material selection and tooling to prototyping and volume production. Whether you need functional components or aesthetic enclosures, we provide tailored solutions with fast turnaround, excellent repeatability, and competitive pricing. We’re trusted by startups and large manufacturers alike for our technical support, attention to detail, and commitment to long-term client satisfaction.